Generations : interpreting Iron Age ceramics

digital ceramics, 2025.

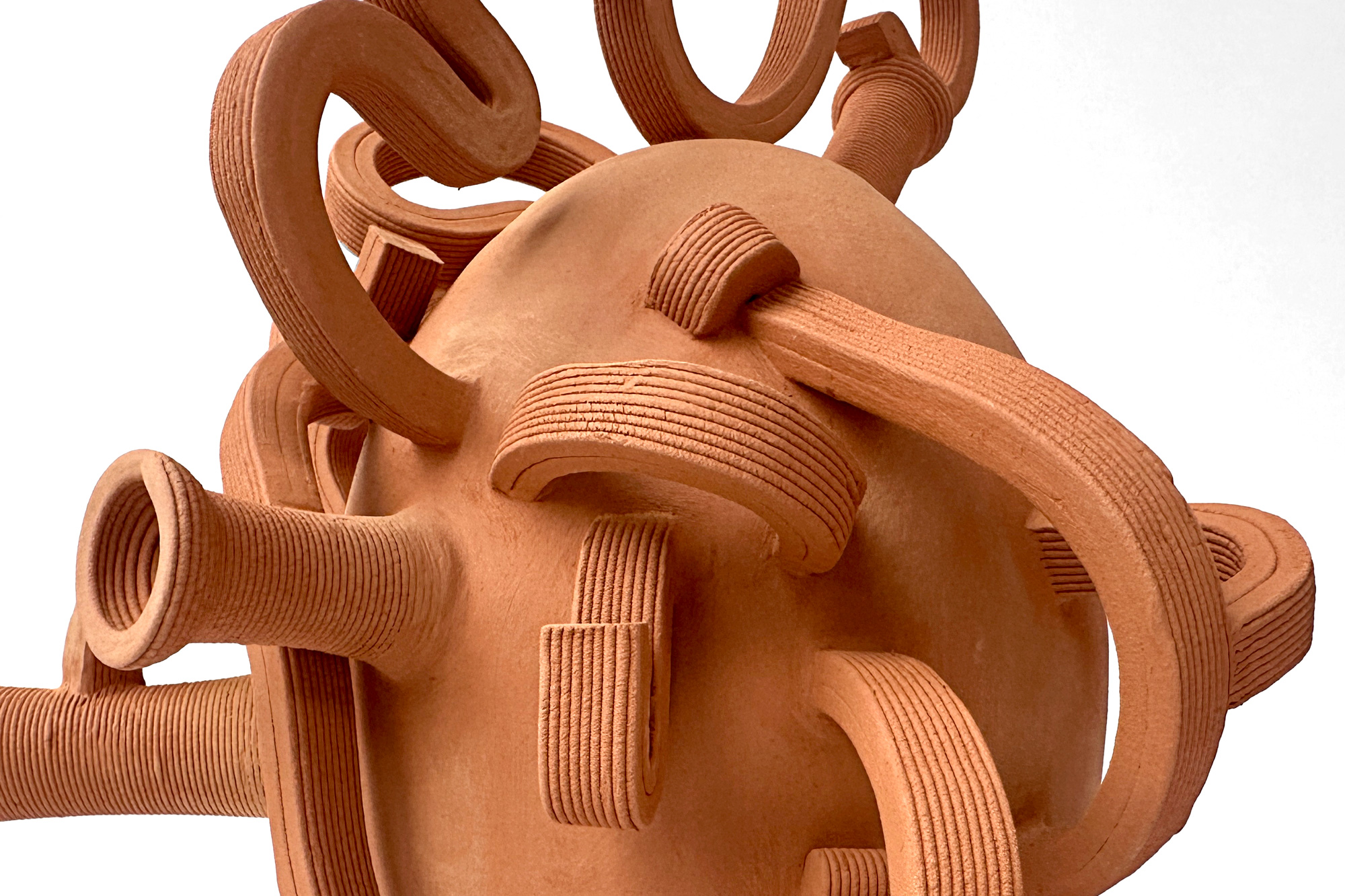

This is a collaborative project with ceramicist Anna Andersen that explores generative AI as a creative tool in ceramic practice. Building on our earlier experiments in A pot, we're working in dialogue with Iron Age vessels (500 BC - 400 AD) from Horsens Museum in Denmark—pots excavated across Horsens Municipality, from well-known burial sites like Hedegård to everyday building and highway construction sites. As makers, what draws us to these pots is that they're more complex than they look. Iron Age ceramics in Denmark were used for everything from cooking to burial rituals; these types of pots can often show surprisingly sophisticated craft for their time. To engage with these historical forms, we use AI in our working process in two ways: "reconstructing" 3D digital forms from photographs of clay artifacts and generating "Iron Age" vessels from text prompts. We treat these outputs as digital sketches that guide our design process. We then physically build the vessels through clay 3D printing and hand sculpting, creating a practice that blends digital generation, machine work, and handwork.

3D-printed and hand sculpted earthenware, mineral pigment, wax, twine. Various dimensions.

3D-printed and hand sculpted earthenware, mineral pigment, wax, twine. Various dimensions.

Set detail.

Mug vase and Window jar; 3D printed and hand sculpted earthenware, wax and mineral pigment, 2025. 15 x 15 x 35 cm and 18 x 18 x 20 cm.

Mug vase and Window jar; 3D printed and hand sculpted earthenware, wax and mineral pigment, 2025. 15 x 15 x 35 cm and 18 x 18 x 20 cm.

Detail, Mug vase.

Fracture pot and Ear urn; 3D printed and hand sculpted earthenware, wax and mineral pigment, 2025. 20 x 20 x 26 cm and 19 x 19 x 31 cm.

Fracture pot and Ear urn; 3D printed and hand sculpted earthenware, wax and mineral pigment, 2025. 20 x 20 x 26 cm and 19 x 19 x 31 cm.

Detail, Ear Urn.

Wavy jar and Standing jug; 3D printed and hand sculpted earthenware, wax, mineral pigment, twine, 2025. 20 x 19 x 24 cm and 20 x 20 x 38 cm.

Wavy jar and Standing jug; 3D printed and hand sculpted earthenware, wax, mineral pigment, twine, 2025. 20 x 19 x 24 cm and 20 x 20 x 38 cm.

Iron Age pot, excavated in Horsens, DK.

AI-generated 3D model of an Iron Age pot.

Fracture pot; 3D-printed and hand sculpted earthenware. 20 x 20 x 26 cm.

Iron Age pot, excavated in Horsens, DK.

AI-generated 3D model of a “Danish Iron Age pot excavated in Horsens, Denmark.”

Window jar; 3D-printed and hand sculpted earthenware, wax. 18 x 18 x 20 cm.

A pot : experiments with clay + gen AI

digital ceramics, 2024 - 2025.

A pot is a collaboration with ceramicist Anna Andersen exploring generative AI as a design tool in ceramic practice. We're interested in whether AI can enhance our creative work without undermining the hands-on, material qualities that define ceramics. Our process positions AI as a creative support tool, not a replacement for human craftsmanship. In the studio, we generate and evaluate hundreds of AI outputs, selecting forms with creative potential. Each AI-generated sketch (3D model) becomes a starting point that we alter, remix, and interpret through our design sensibilities and understanding of clay; we then translate digital to physical through clay 3D printing and hand sculpting. A pot tests how emerging technologies might expand creative possibilities within traditional art and craft practices centered on tactility, intuition, and human expression.

A pot has recieved development support from Nationalbankens Jubilaeumsfond.

A pot has recieved development support from Nationalbankens Jubilaeumsfond.

3D-printed and hand sculpted red clay, various dimensions (largest is 35 x 30 x 40 cm).

A pot with handles, 3D-printed and hand sculpted red clay.

Vase with necks, 3D-printed and hand sculpted red clay.

Double Amphora, 3D-printed and hand sculpted red clay.

Detail, Vase with necks.

AI-generated model of “a pot” - what we consider an initial “digital sketch.”

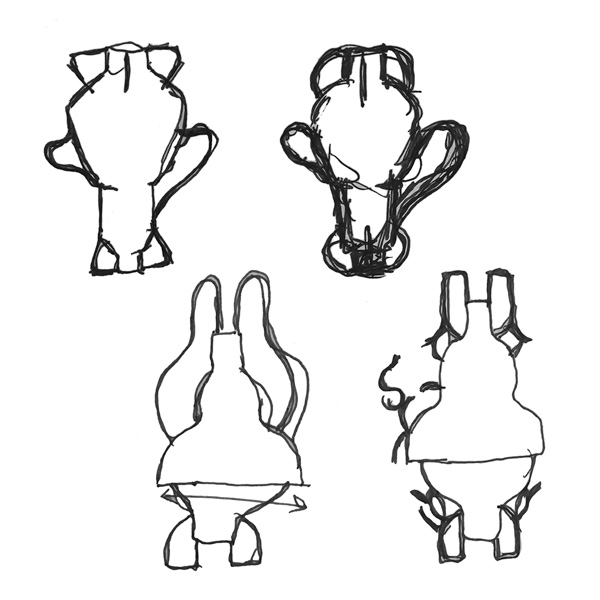

Artist sketches for a pot.

First version of Double Amphora.

AI-generated model of “a pot”.

AI-generated model of “a pot”.

AI-generated model of “a pot”.

Two of our first AI-generated 3D models.

Glazing one of the models, 3D-printed in red clay.

Glazing one of the models, 3D-printed in red clay. Beaker, 3D-printed red clay, slip wash, glaze.

Beaker, 3D-printed red clay, slip wash, glaze.Clay 3D Printer

studio tool, 2019 - ongoing

My journey with clay 3D printing began unexpectedly in 2019 while building a Digital Fabrication Studio at Montserrat College of Art. Despite having no prior experience with ceramics, I fell in love with the unique qualities of clay as a material and the machine expressions that arise from the clay 3D printing process. This initial fascination led me to take a ceramics course and begin experimenting with a Potterbot clay printer to better understand the technology and its possibilities.

First clay printing experiments with a Potterbot, 2019.

First clay printing experiments with a Potterbot, 2019.

First 3 “vases” in 3D-printed porcelain, 2019.

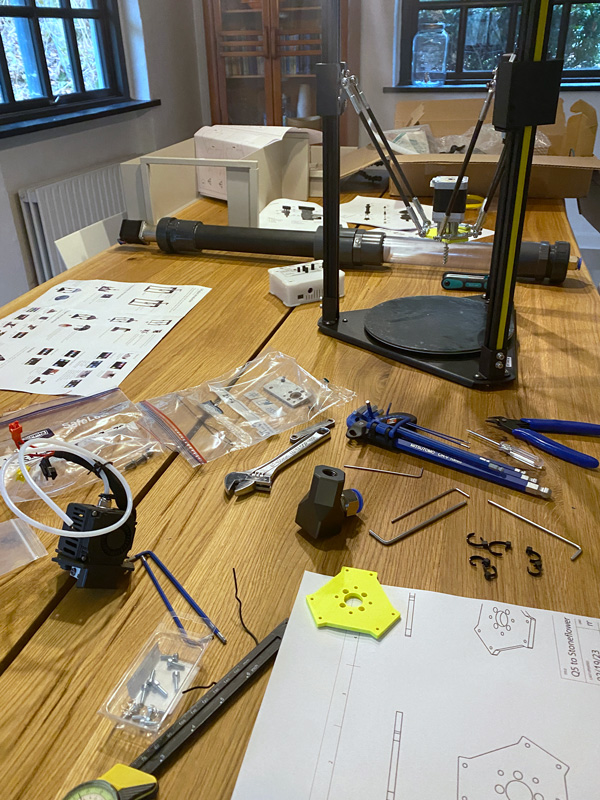

This tool-building project took shape in 2022 when I received an Art/Tech Artist-in-Residence grant that allowed me time and support to build my own custom clay printer. I started by visiting ceramicist Anna Andersen, who works with two different types of self-built clay printers. For my printer build, I decided to combine the strengths of two existing systems: an FLSun Q5 delta printer, chosen for its stepper motors and accessible motherboard, paired with a Stoneflower 3D Ceramic printer kit that provided mechanical ram extrusion and the option for independent clay extrusion controls.

The technical development involved designing a custom mount for the printhead and modifying the firmware to accommodate the hybrid setup and custom wooden build plates. I also created custom G-code and slicing profiles using Prusa Slicer, which was already integrated with my existing 3D printing studio workflow.

The technical development involved designing a custom mount for the printhead and modifying the firmware to accommodate the hybrid setup and custom wooden build plates. I also created custom G-code and slicing profiles using Prusa Slicer, which was already integrated with my existing 3D printing studio workflow.

Researching a DIY printer build - studio visit with ceramicist Anna Andersen, Horsens, DK.

Researching a DIY printer build - studio visit with ceramicist Anna Andersen, Horsens, DK.

Assembling the delta printer and designing a custom printhead mount.

Dialing in custom z heights for firmware and slicer settings.

First day of operation in FabLab Spinderihallerne, Vejle, DK.

Testing printer operation and slicer settings.

It’s alive! Printing with stoneware clay.

Printer setup in studio with wall-mounted ram extruder.

After completing the build in 2023, I spent time calibrating the system and testing various types of 3D forms and clay types. The printer has since been exhibited at the Silicon Vejle festival in Vejle, DK and has become an integral tool for several of my projects, including Jord/Luft, Vibrant Soils, and Jordforbindelse. Currently, it's helping me create prototypes for my latest experimental work combining generative AI with ceramics, A pot.

Testing forms and clay bodies.

Experiments with slicer settings.

Printer on location outdoors at Silicon Vejle city festival, 2023.

Special thanks to Anna Andersen, Andrew Sliwinski and the folks at FabLab Spinderihallerne for their support and advice during the build.

Some things I found helpful:

+ Jonathan Keep’s guide to clay 3D-printing

+ Stoneflower 3D’s Ceramic 3D printer kit

+ Wikifactory Ceramic 3D printing forum

Some things I found helpful:

+ Jonathan Keep’s guide to clay 3D-printing

+ Stoneflower 3D’s Ceramic 3D printer kit

+ Wikifactory Ceramic 3D printing forum

Mirror Stage

exhibition, Vejle Kunstmuseum, 2024 - 2025

In an era where image manipulation is commonplace, the relentless pursuit of physical ideals both on screens and in real life raises some questions. What defines the perfection we seek in our physical faces and bodies? Mirror Stage attempts to blend classical ideals and new technologies in order to interrogate our societal notions of bodily perfection and our evolving connection to new technologies.

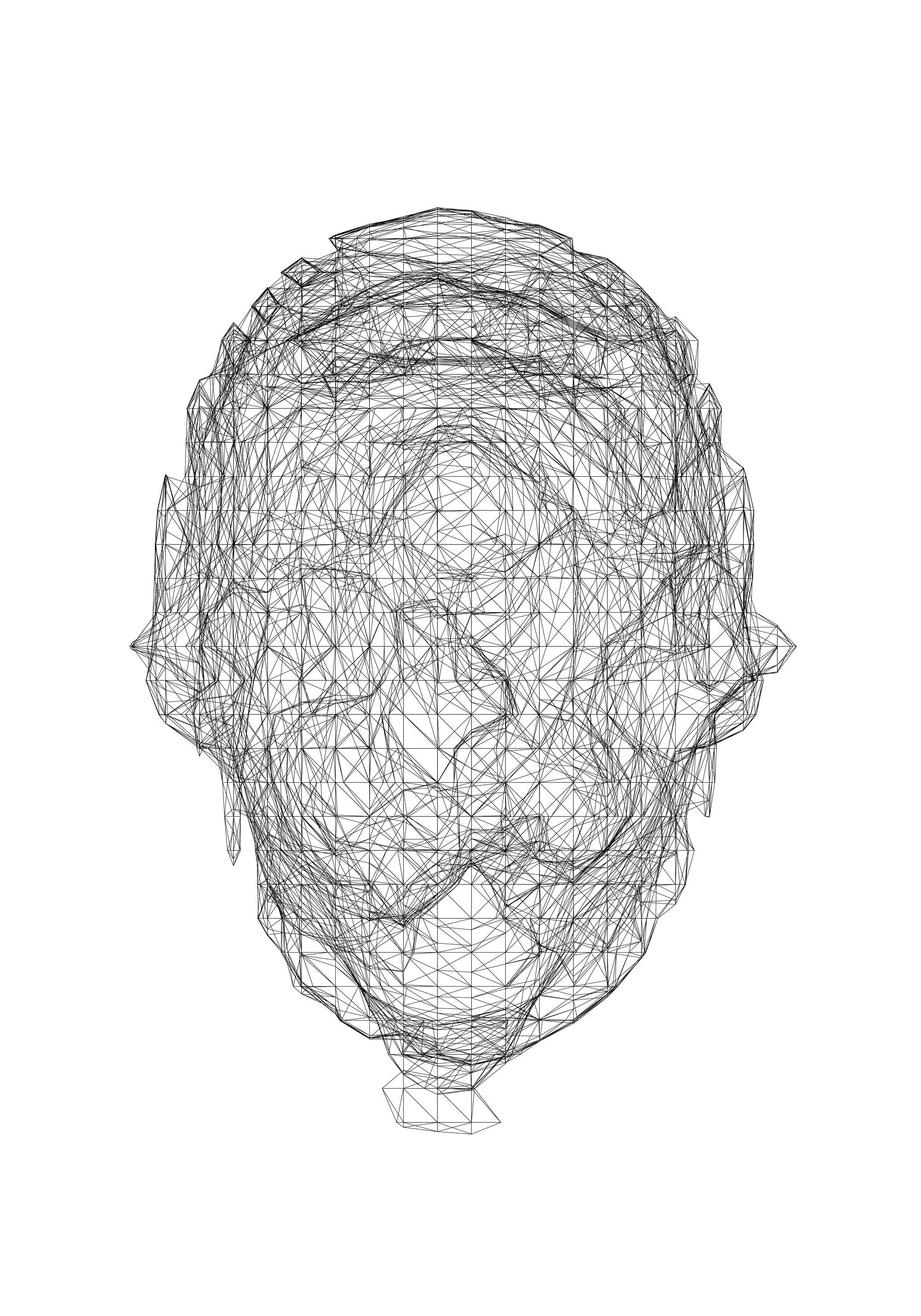

Mirror Stage is a collaborative venture between myself and artificial intelligence. At the heart of this endeavor is the use of text prompts to engage a machine learning system that generates 3D digital objects. Guided by prompts inspired by the physical ideals found in classical Western sculpture, such as 'a delicate female face' or 'the strong face of a god,' the system and I try to imagine and sculpt the quintessential human visage.

This experiment is a play between human expression and machine interpretation, existing in the uncanny valley between the digital and the tangible. The resulting forms embrace and attempt to highlight the glitches and imperfections that are always inherent in emerging technologies. Here AI is in the spotlight, as it operates using vast data sets created and aggregated by humans; the imperfections inherent in this particular technology are directly connected to our own. Mirror Stage is a challenge to reconsider our perception of the flawless and to question our evolving relationships with the machines and systems that increasingly shape our daily lives. As we humans navigate this emerging landscape, Mirror Stage aims to be a mirror reflecting not only our ideals but also the complexities of our existence in an age of relentless technological innovation.

This project is shown as a part of the group exhibition Kropumulig Kroputrolig at the Vejle Kunstmuseum in Vejle, DK. The exhibition was curated by Trine Grøne and features artists Mia Mai Dengsø Graabæk, Soren Thilo Funder and Lærke Posselt. Exhibition images courtesy of Kenneth Stjernegaard and Vejle Kunstmuseum. Funding for realizing this work courtesy of Statens Kunstfond and Vejle Kunstmuseum.

+ Vejle Museums’ Exhibition Page

+ Press Release

Mirror Stage is a collaborative venture between myself and artificial intelligence. At the heart of this endeavor is the use of text prompts to engage a machine learning system that generates 3D digital objects. Guided by prompts inspired by the physical ideals found in classical Western sculpture, such as 'a delicate female face' or 'the strong face of a god,' the system and I try to imagine and sculpt the quintessential human visage.

This experiment is a play between human expression and machine interpretation, existing in the uncanny valley between the digital and the tangible. The resulting forms embrace and attempt to highlight the glitches and imperfections that are always inherent in emerging technologies. Here AI is in the spotlight, as it operates using vast data sets created and aggregated by humans; the imperfections inherent in this particular technology are directly connected to our own. Mirror Stage is a challenge to reconsider our perception of the flawless and to question our evolving relationships with the machines and systems that increasingly shape our daily lives. As we humans navigate this emerging landscape, Mirror Stage aims to be a mirror reflecting not only our ideals but also the complexities of our existence in an age of relentless technological innovation.

This project is shown as a part of the group exhibition Kropumulig Kroputrolig at the Vejle Kunstmuseum in Vejle, DK. The exhibition was curated by Trine Grøne and features artists Mia Mai Dengsø Graabæk, Soren Thilo Funder and Lærke Posselt. Exhibition images courtesy of Kenneth Stjernegaard and Vejle Kunstmuseum. Funding for realizing this work courtesy of Statens Kunstfond and Vejle Kunstmuseum.

+ Vejle Museums’ Exhibition Page

+ Press Release

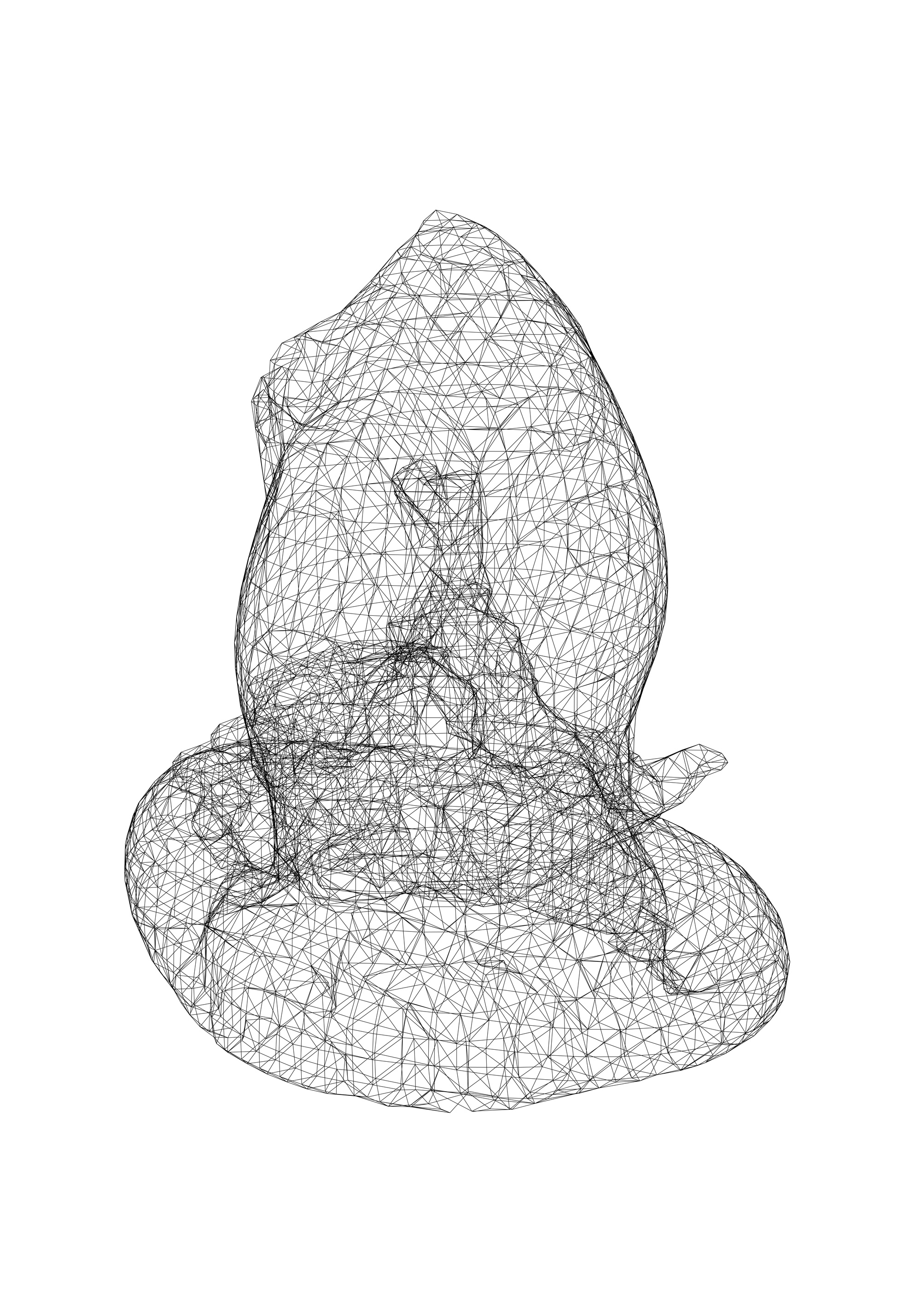

A head with flowing hair, archival inkjet print of AI-generated mesh, 70 x 100 cm.

A head with flowing hair, archival inkjet print of AI-generated mesh, 70 x 100 cm.

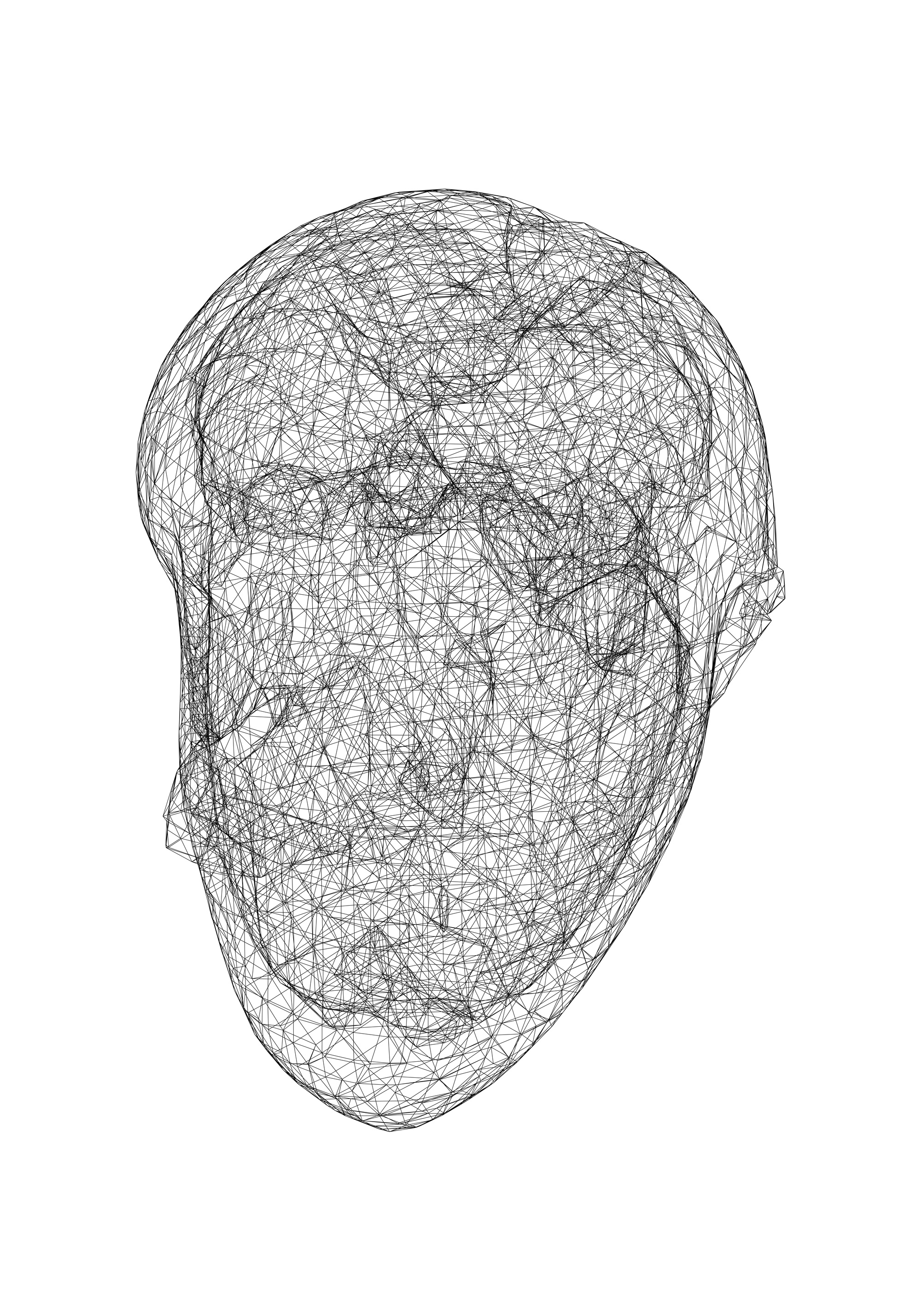

A delicate female face, archival inkjet print of AI-generated mesh, 70 x 100 cm.

A beautiful visage, archival inkjet print of AI-generated mesh, 70 x 100 cm.

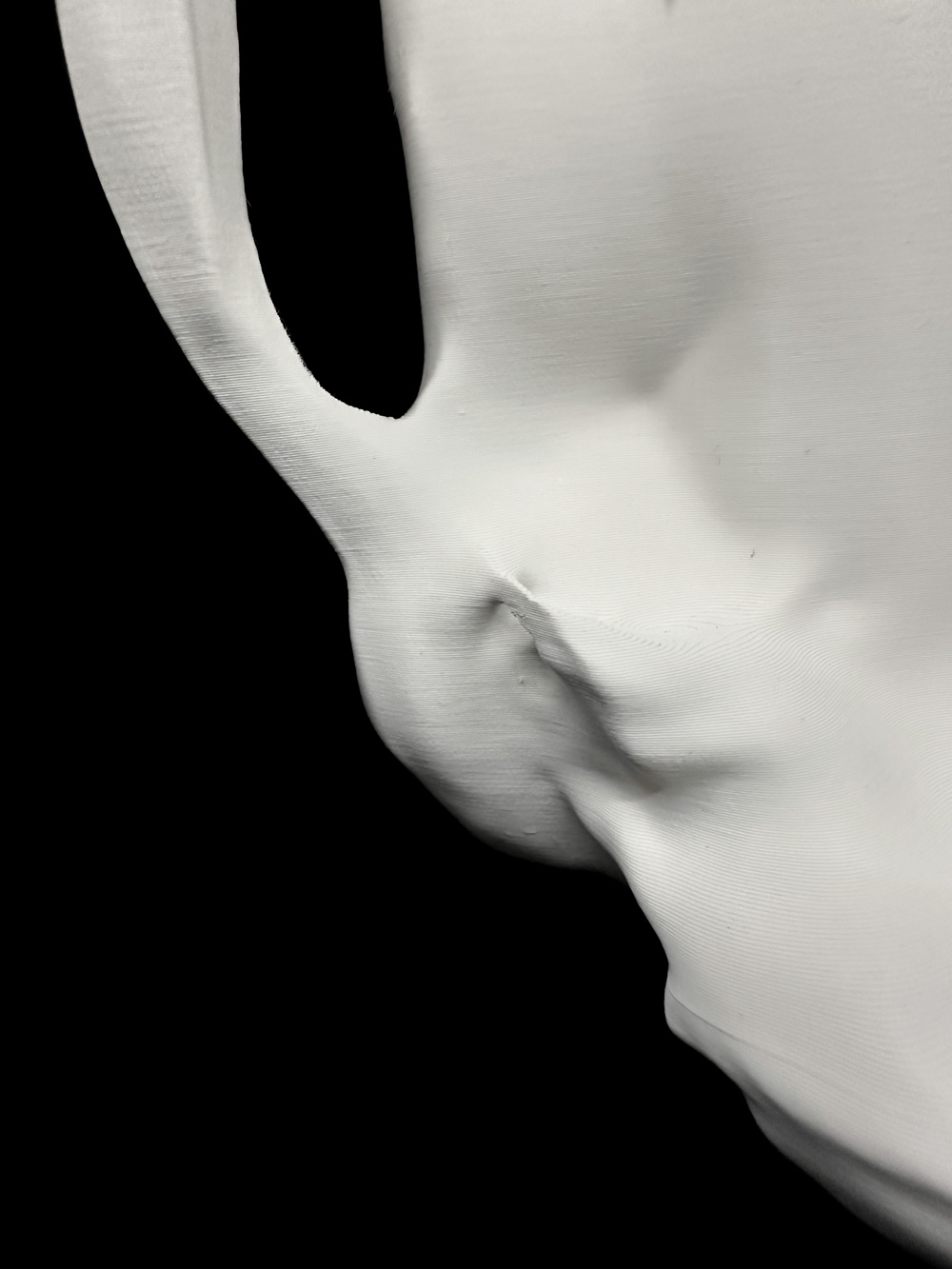

A perfect human face, 3D-printed plaster/bioplastic, 16 x 16 x 19 cm.

A perfect human face, 3D-printed plaster/bioplastic, 16 x 16 x 19 cm. Detail.

Detail.

An ideal face, 3D-printed plaster/bioplastic, 19 x 13 x 16 cm.

The face of a god, 3D-printed plaster/bioplastic, 12 x 10 x 15 cm.

Detail.

Detail. Surface detail.

Surface detail.25 attempts at making a vase

digital ceramics, 2024

This work is exactly as the title describes; 25 attempts at making a vase. The pieces included in this collection are artifacts from the process of learning how to 3D print with clay, each comes from experiments with different forms, tools and clay bodies.

Unique. 3D printed stoneware and porcelain, various dimensions. Objects vary between approx. 26 x 12 cm and 5 x 7 cm; Configuration as pictured, 167 x 30 x 30 cm.

Detail.

Detail.