Clay 3D Printer

studio tool, 2019 - ongoing

My journey with clay 3D printing began unexpectedly in 2019 while building a Digital Fabrication Studio at Montserrat College of Art. Despite having no prior experience with ceramics, I fell in love with the unique qualities of clay as a material and the machine expressions that arise from the clay 3D printing process. This initial fascination led me to take a ceramics course and begin experimenting with a Potterbot clay printer to better understand the technology and its possibilities.

First clay printing experiments with a Potterbot, 2019.

First clay printing experiments with a Potterbot, 2019.

First 3 “vases” in 3D-printed porcelain, 2019.

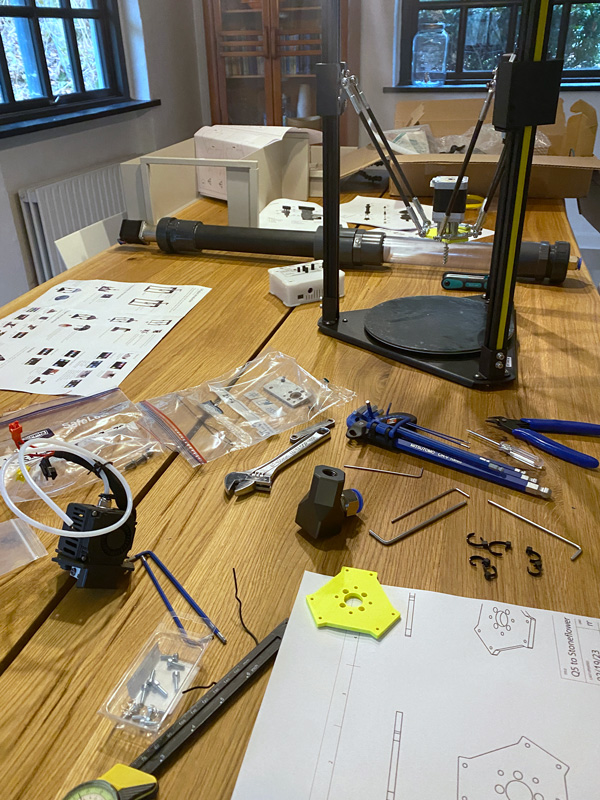

This tool-building project took shape in 2022 when I received an Art/Tech Artist-in-Residence grant that allowed me time and support to build my own custom clay printer. I started by visiting ceramicist Anna Andersen, who works with two different types of self-built clay printers. For my printer build, I decided to combine the strengths of two existing systems: an FLSun Q5 delta printer, chosen for its stepper motors and accessible motherboard, paired with a Stoneflower 3D Ceramic printer kit that provided mechanical ram extrusion and the option for independent clay extrusion controls.

The technical development involved designing a custom mount for the printhead and modifying the firmware to accommodate the hybrid setup and custom wooden build plates. I also created custom G-code and slicing profiles using Prusa Slicer, which was already integrated with my existing 3D printing studio workflow.

The technical development involved designing a custom mount for the printhead and modifying the firmware to accommodate the hybrid setup and custom wooden build plates. I also created custom G-code and slicing profiles using Prusa Slicer, which was already integrated with my existing 3D printing studio workflow.

Researching a DIY printer build - studio visit with ceramicist Anna Andersen, Horsens, DK.

Researching a DIY printer build - studio visit with ceramicist Anna Andersen, Horsens, DK.

Assembling the delta printer and designing a custom printhead mount.

Dialing in custom z heights for firmware and slicer settings.

First day of operation in FabLab Spinderihallerne, Vejle, DK.

Testing printer operation and slicer settings.

It’s alive! Printing with stoneware clay.

Printer setup in studio with wall-mounted ram extruder.

After completing the build in 2023, I spent time calibrating the system and testing various types of 3D forms and clay types. The printer has since been exhibited at the Silicon Vejle festival in Vejle, DK and has become an integral tool for several of my projects, including Jord/Luft, Vibrant Soils, and Jordforbindelse. Currently, it's helping me create prototypes for my latest experimental work combining generative AI with ceramics, A pot.

Testing forms and clay bodies.

Experiments with slicer settings.

Printer on location outdoors at Silicon Vejle city festival, 2023.

Special thanks to Anna Andersen, Andrew Sliwinski and the folks at FabLab Spinderihallerne for their support and advice during the build.

Some things I found helpful:

+ Jonathan Keep’s guide to clay 3D-printing

+ Stoneflower 3D’s Ceramic 3D printer kit

+ Wikifactory Ceramic 3D printing forum

Some things I found helpful:

+ Jonathan Keep’s guide to clay 3D-printing

+ Stoneflower 3D’s Ceramic 3D printer kit

+ Wikifactory Ceramic 3D printing forum